M-300EM

M-300EM is the largest single chamber model in our series. All stainless steel Mobile model (Floor model) with deep drawn vacuum chamber of rounded corners for optimum cleanliness and the least particle count. Aluminum lid with clear window cover helps visual quality assurance. Extra seal bar configurations are available. The deep chamber design gives you the flexibility in vacuum packing large profile products as well as the small, low profile items using A Space Filler that comes with the machine to adjust the usable chamber heights and net payload volume. 10 program capability offers the ultimate in process control.

Product Specifications

AMAC M-300EM is a large capacity vacuum packaging machine for Semicon, Chips, Motherboards, and countless other Electronics Applications and Disposable Surgical Packages, IV Bags and other Medical Applications for Hospitals, Surgical Centers and Clinics.

Additional Info & Options

The robust, stainless steel AMAC M-300EM vacuum packer is standard equipped with a Busch vacuum pump. The machine is ETL listed and complies with CE standards.

Would you like to know more about this and any of our other products in the series?

The robust, stainless steel AMAC M-300EM vacuum packer is standard equipped with a Busch vacuum pump. The machine is ETL listed and complies with CE standards.

- Base models engineered for user-friendly operations and with robust construction

- For manufacturers and contract packaging companies with low to medium volume production demand.

- Perfect fit for first time vacuum packing experiences

- Flexible for Various Size Products

- Totally made of stainless steel

- Optimal hygiene and low particle counts.

- Cleanroom use

- Aluminium lid with clear window

- Progressive aeration of chamber

- Economically priced

- Space Filler for faster cycle and adjusting seal height

FAST AND ROBUST VACUUMPACKAGING

MACHINES WITH WORLD WIDE REPUTATION

- Robust single chamber vacuum packaging machine

- Complete range for vacuum and MAP packaging solutions

- Extensive program choices for specific packaging requirements

- Industrial machine for an attractive price

- User friendly and low maintenance supplied with complete service program

- Optional data Acquisition and industrial network solution

Specifically engineered for

Electronics – Semi-conductors – IC Boards, Wafers, Metal Parts and Components – General Machines and Aviation Items, Sharp and Fragile Items, Textiles, Museum Items, Coins, Bills, collectibles

Pharmaceutical Products – Disposable Hospital Supplies, Laboratory Items, etc.

- Moisture free packaging

- Air and dust-free packaging

- Volume reducing packaging

- Scrapes and scratches free solution

- Fraud resistant packaging

- Sterile and contamination free packaging

- Antistatic packaging (ESD)

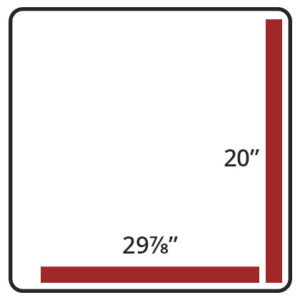

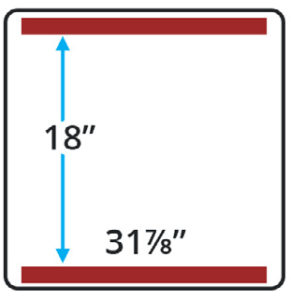

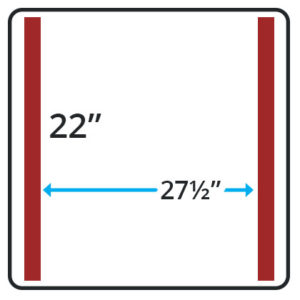

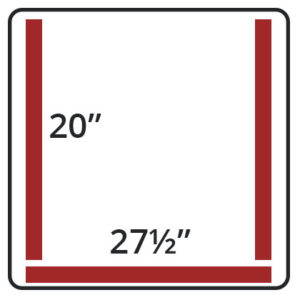

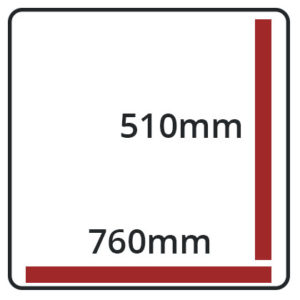

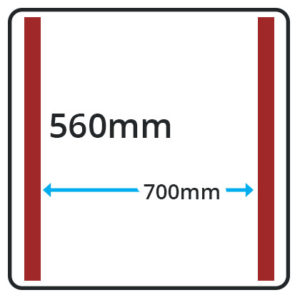

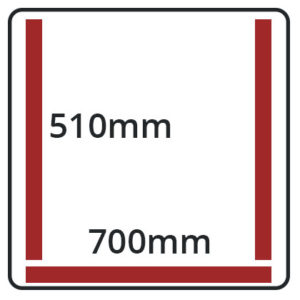

- Seal bar length: 20” / 29?” (510 mm / 760mm)

- Different seal bar configuration available

- Seal bar with two wires, for double security

- Seal bar easily removable for cleaning and maintenance purposes

- Pump capacity: 70.62 CFM (120 m3/h) Busch vacuum pump

- Pump maintenance and cleaning program

- Machine cycle: 15-40 sec

- Sensor control: 1-99.8%, for an optimum and consistent vacuum and cycle time.

- Cushion protection control to protect the product and vacuum pouch

- 10 program memory

- Aluminum lid with clear window which opens automatically after every cycle

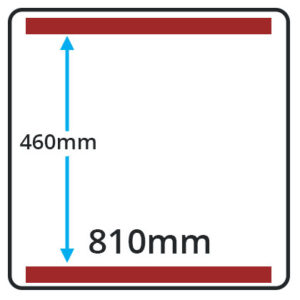

- Deep drawn vacuum chamber

- Comes with a space filler for a faster cycle and product adjustment

- Stainless steel exterior

- 6ft cord with Nema 14-50P plug

- Gas injection

- Top and bottom seal

- Trim off seal

- 8 mm seal width

- Third seal bar

- 1-2 trim off seal

- Precision Control System with 20 programs

- Service kit for standard maintenance

- Space filler