Electronic Vacuum Packaging for Product Protection

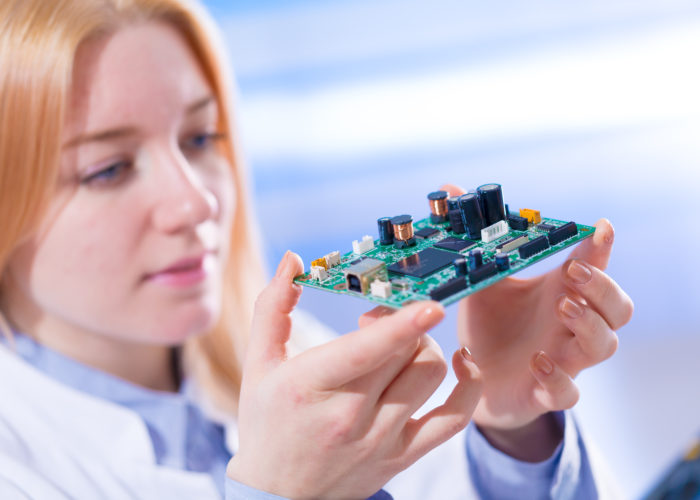

AMAC offers the widest variety of features and options for our electronics vacuum packaging machines. The robust, stainless steel AMAC vacuum packer is equipped standard with a Busch vacuum pump. The machine complies with CE standards and ETL listed as an option. Our vacuum sealers for electronics components seal all types of delicate electronic products including semiconductors, microchips, memory chips, sub panels, motherboards, PLC’s, RAM, and much more.

An AMAC vacuum sealing machine for electronics uses sensor-control for gas injections in order to prolong the shelf life of all products as well as protect from the decay factor of oxidation. Vacuum packaging protects against dust, damage, ultraviolet and radio frequency contamination (when used with appropriate barrier bags), electrostatic discharge, humidity oxidization, and corrosion. AMAC industrial packaging machines are the electronics industry solution to streamline your workflow and protect your valuable electronic products. If you are looking for an advanced vacuum sealer for electronics components, our selection is the perfect place to start your search.

Should you require a vacuum sealing machine for electronics, you can contact us and we can help you choose the best product for your needs.

Tabletop

AMAC tabletop machines are the ideal solution for quick and easy sealing of electronic products. The compact design of the tabletops make these units flexible and convenient. Designed for smaller electronics products like microcontrollers, wafers and memory chips. All AMAC machines in the “T” series have a clear chamber lid that permits one to view the packaging procedure. The tabletop vacuum machines provide the highest quality output for electronics packaging.

Mobile

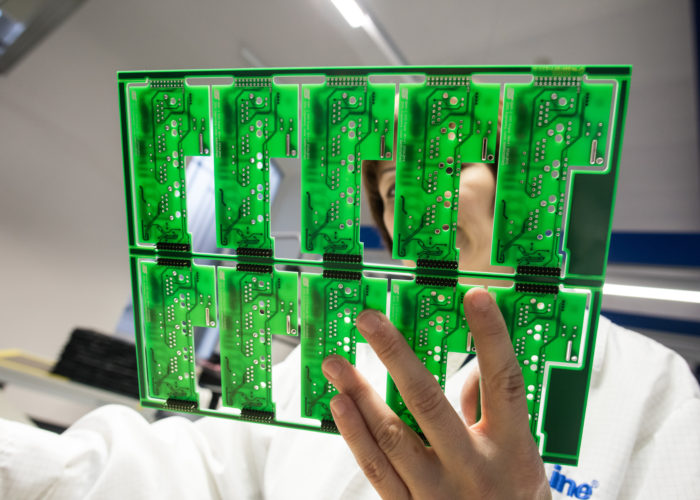

Mobile chamber machines are larger than the tabletops and fashioned with floor casters for fast relocations. Designed for larger electronics such as integrated circuits, motherboards, and production PCBs. Chamber vacuumed packaged electronics are ESD safe and protect oxygen-sensitive electronics. The evacuation and gas flushing processes are pressure-controlled and thus guarantee a reproducible packing quality. Save space and production with the AMAC mobile series vacuum machines.

Double Chamber

The dual chamber vacuum sealer increases production in electronics packaging. While products are being sealed in the first chamber, the second chamber can be unloaded and loaded again. Double chamber vacuum sealing machines offer the highest output on the smallest footprint. The electronic components are sealed air-tight and oxygen free. AMAC chamber machines are designed for exceptional durability.

Nozzle Vacuum Sealer Machines

AMAC specializes in professional nozzle vacuum sealing machines. Our optimum quality nozzle packaging machines are a versatile solution to the vacuum sealing problems facing electronic businesses. Our nozzle vacuum sealing machines are designed for exceptional durability. AMC nozzle sealing machines combine efficiency and affordability to provide ideal electronics vacuum sealing results.

Extensive Features Means the Perfect Sealing Solution

- AMAC offers various models designed and tested to provide precise performance.

- Get up and running quickly with the easy step-by-step guide or our well-trained support staff.

- Quick and easy adjustments for the height and plates.

- Available barcode printing implementation with data collection and data analytics.

- Our AMAC machines are designed to streamline the packaging production process.

- Rigorously tested to ensure your product is sealed and protected.

Perfect Solutions for your Electronics Packaging

- Built from stainless steel, these sealers offer optimal hygiene and low particle counts.

- Seal semiconductor electronics and computer electronics like motherboards, processors, and RAM memory.

- Protect your electronic products from the oxidation decay factor!

- Prevent triboelectric charging which leads to electrostatic discharge (ESD)

- AMAC vacuum packaging material are engineered to meet any clean-room standards.

- AMAC vacuum package material protects your product against dust, ultraviolet light, radio frequency contamination, humidity, and more.